Connected Devices, Digital Manufacturing and Industry 4.0

Industry 4.0, the Fourth Industrial Revolution, promises a brave new world of fully automated production that is responsive to circumstances and controlled by computers. Digital Manufacturing is a compelling vision, where the role of AI goes further than monitoring the production process by improving it, and even anticipating problems before they occur.

However, taking on the challenge of fully automated manufacturing will prove expensive, and amidst all the hype and promise, it is equally challenging for organisations to know where to start. For this reason, Business Case, Feasibility Studies and pilot projects are commonplace, as organisations seek to understand the potential and the promise of a return on investment.

Gathering Data is All Very Well, but ‘So What?’

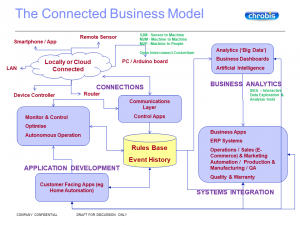

Equally important is to use your research or feasibility stage to develop a ‘Business Architecture‘ to clarify what exactly it is you are trying to achieve, which data will deliver your business case, and how, and how you are going to exploit the data that will be collected.

Typical applications will be in:

- Monitoring device condition, operation and performance in different circumstances

- Responding automatically to control the device, to adjust to changes in conditions, both internal and external to it

- Optimising operations to improve output, function or efficiency of the device

- Developing fully autonomous operations

Continuous collection of historical data and operations will also provide an historical event history to create a rule base from which to further improve device operation from learned behaviour.

Embedding New Capability into Your Organisation

The business case for Digital Manufacturing may initially be strong purely on the ‘technical’ level of connecting devices. However, it is when cognitive capability is applied on top of the collected data that the real power of technology emerges, overlaying connected devices with Intelligent Automation, Cognitive Insight through Big Data Analysis, or Cognitive Engagement with employees to improve business processes, increase competitiveness and drive production efficiency.

We see three broad areas where organisations should look to examine their current ways of working to think through improvements for their business:

- Customer Facing applications – can the data collected allow you to change the way you offer your product or service to the customer? Can you deploy ‘Product as a Service’ by selling the service that your product provides rather than the product as a product?

- Business Analysis / Predictive Analytics – can the data provide insights into your business operations, or customer activity that enable you to compete differently in the market?

- Integration into your Business – Operations, ERP, E-Commerce, Marketing and Customer Service – to improve your operational efficiency?

In Summary

Data Collection from connected devices and Big Data mean nothing if you cannot analyse, understand and adjust your business practices as a result and make a difference for your customer. To get started with your project, or simply to discuss your ideas, email [email protected].